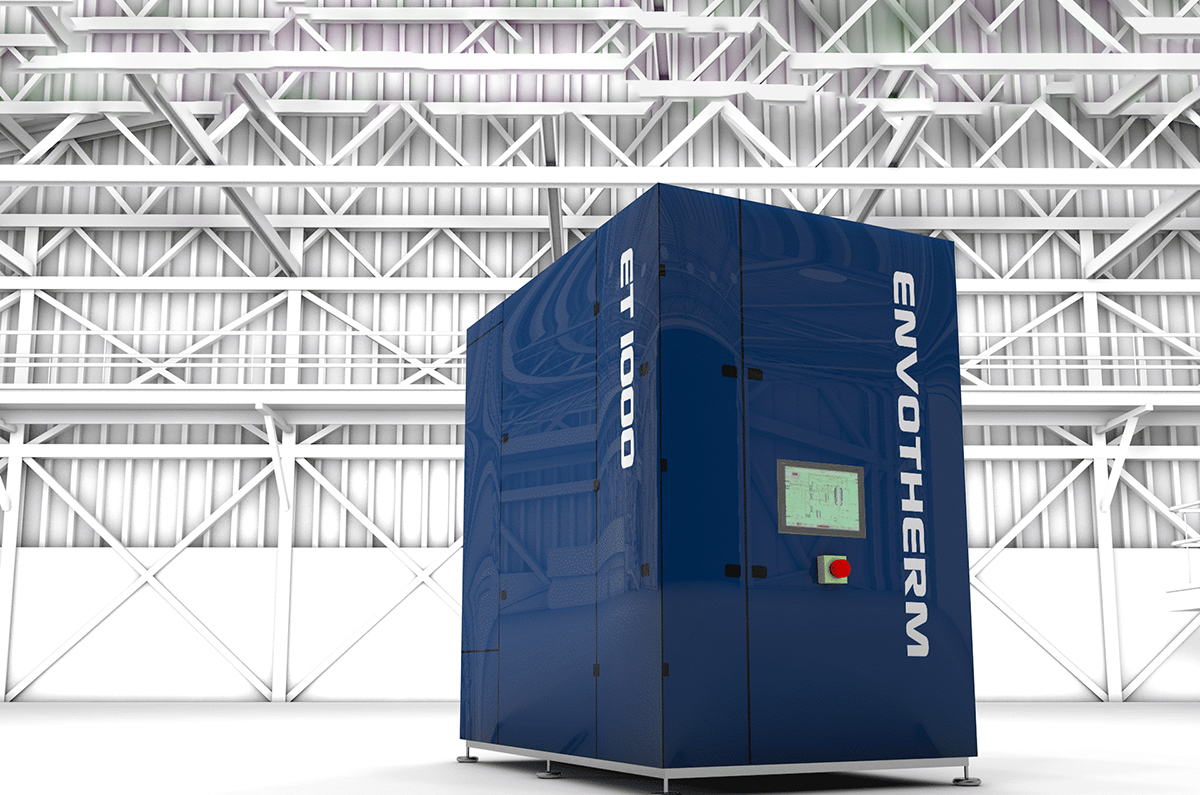

Envotherm

Envotherm, innovative technology for clean wastewater

Pure water – less energy

Does your company have a production facility that uses water for the processing or cleaning of your products? Envotherm Solutions has the solution for companies that want to recycle and recirculate resources and prevent unnecessary industrial wastewater disposal.

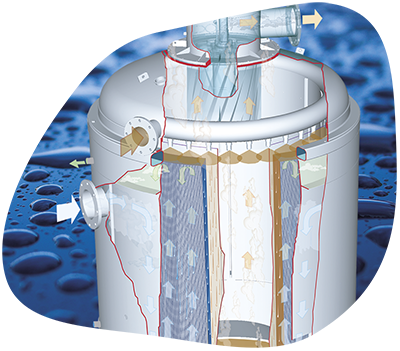

Envotherm, E-MVR the technology behind it

The technology behind it is called pressure-neutral evaporation. Pressure Neutral Evaporation has many advantages compared to other/comparable systems. Envotherm's technological platform is therefore based on fulfilling these natural properties = energy savings. In our universe, all organisms and elements strive for the lowest energy level/consumption.

Pressure neutral evaporation:

- Coalescence separation on the distillate.

- Patented absorbent technology.

- Vertical cylindrical evaporator - Less foam - Less impurities.

- e-mvr REDUCES SLUDGE BY 95-99%

- Durable and strong construction.

- All parts comply with ISO/DIN standards - AISI 316L/W.

- Internet monitoring - Remote control.

E-MVR

E-MVR is Envotherm's patented technology for efficient, sustainable and cost-effective evaporation of wastewater. With E-MVR you have advanced and reliable technology that guarantees your efficiency for years to come.

E-MVR is Envotherm's patented technology for efficient, sustainable and cost-effective evaporation of wastewater. With E-MVR you have advanced and reliable technology that guarantees your efficiency for years to come.

The E-MVR technology separates the industrial wastewater into two fractions; a concentrate (1-5%); and a distillate (95-99%). Envotherm guarantees purity

of the distillate.

For who?

In many industries, water-intensive processes create large quantities of industrial wastewater that cannot be discharged,

but do require physical, chemical or biological treatment. This innovative technology for clean wastewater is suitable for large and small production companies

where water is used as the main ingredient for processing or cleaning products. These patented purification installations can also be used to reuse the contaminated washing water from industrial cleaning machines. Also in the High Tech industry where cleanliness is at such a high level, the use of such a system that cleans process water is interesting to make the company more sustainable, cost-saving and cleaner.

Metal industry

Metal industry

This solution is suitable for companies involved in turning and milling operations in the metal industry to remove oil, cooling lubricants, grease, polishing paste, soot and metal chips and to guarantee a consistently high quality of the surface. It is also reuse to ensure that the water can be used again in the process. This is one of the arguments why the ET-Compact system is attractive for metalworking, among others.

Plastic industry

Suitable for companies that process plastic parts, where you often meet the same (high) requirements as in the metal industry.

The advantages

- Can recycle up to 99% of wastewater.

- Lowest energy consumption on the market (15 - 45 kWh/m³).

- Plug and play solution.

- Capacity from 750 m3 to 14.000 m3 per year.

- Self-cleaning.

- Completely automated.

- High level of separation - Wastewater is separated into distillate (pure water) and waste concentrate at only 3-15% of the original amount.

- All heavy metals are effectively removed, e.g.: Chromium (Cr), Nickel (Ni), Zinc (Z3), Cadmium (Ca).

- The evaporation principle and the patented absorption system ensure a distillate of significantly better quality than comparable systems.

- Low COD, no oil, so no after-treatment (chemical or carbon filter) required.

- Reduction of CO2 emissions

- Reduce your ecological footprint through corporate social responsibility.

E-MVR advanced evaporation technology gives you the competitive advantages you need.

E-MVR advanced evaporation technology gives you the competitive advantages you need.

The rules for the disposal of industrial wastewater are becoming stricter and prices are becoming higher. E-MVR technology combines sustainability and cost reduction and illustrates that the green transition can go hand in hand with lower operating costs.

Companies that purchase an Envotherm solution typically see an ROI of 18-36 months. Customers who rent a solution from Envotherm save 30-50% on their costs, starting from the day of installation.

Applications

Envotherm systems clean/separate most types of industrial wastewater, provided the main component is WATER.

- Cutting fluids, cutting oil, slideway oil, preservative oil and other floating oils and other oil-based waste water.

- Wastewater from alkaline cleaning.

- Wastewater from the chemical and pharmaceutical industries.

- Clean water from surface treatment.

- Wastewater containing TEFLON and heavy metals.

- Process water from various industries such as "Electroplating - Glass Production - Ball Cleaning, Ethylene Glycol Purification".

- Separation of organic substances.

- Pressure casting: oil, soap, heavy metals, etc. are effectively separated.

- Even waste water with radioactive content.

Technical data ET Series

Specifications

| Type | ZLD 1 | ZLD 2 | ZLD 3 | ZLD 4 | ZLD 5 | ZLD 6 | ZLD 7 | ZLD 10 |

|---|---|---|---|---|---|---|---|---|

| Capacity Ltr/hour | 150 | 300 | 450 | 600 | 750 | 1000 | 1250 | 2500 |

| Capacity m3 year | 675 | 1350 | 2025 | 2700 | 3375 | 6000 | 7500 | 15.000 |

| Energy KWH/m3 | 45 | 40 | 38 | 35 | 30 | 25 | 22 | 20 |

| Length | 2130 | 2130 | 2130 | 2130 | 2500 | 2500 | 4000 | 4000 |

| Width | 3140 | 3140 | 3140 | 3140 | 3500 | 3500 | 2500 | 2500 |

| Height | 3300 | 3300 | 3300 | 3300 | 3300 | 3300 | 4500 | 4500 |

| Weight | 1050 | 1150 | 1250 | 1500 | 1750 | 4000 | 6500 | 8000 |

| Power connection | 400/440 | 400/440 | 400/440 | 400/440 | 400/440 | 400/440 | 400/440 | 400/440 |

| Frequency | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 |

Video's

CO2 Calculator

Brochure